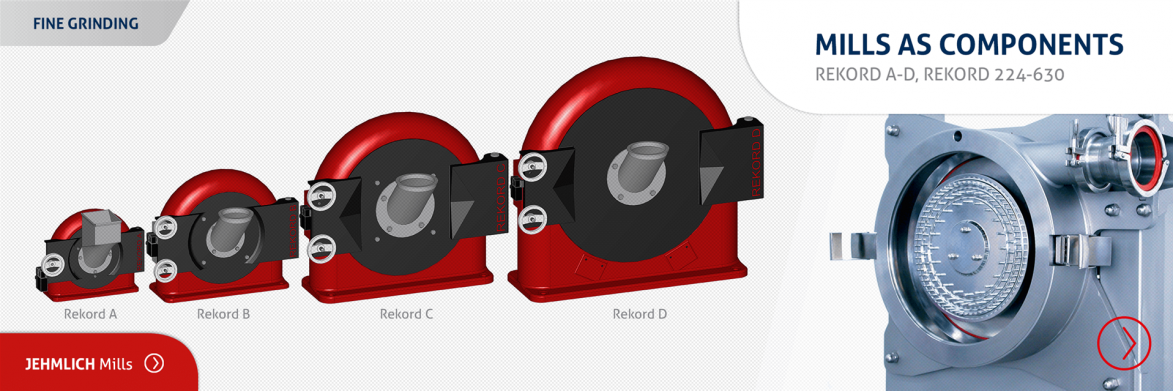

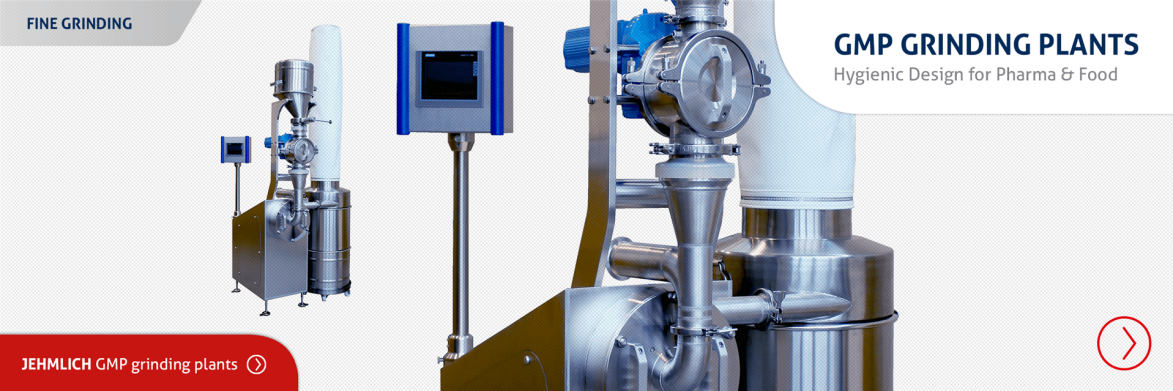

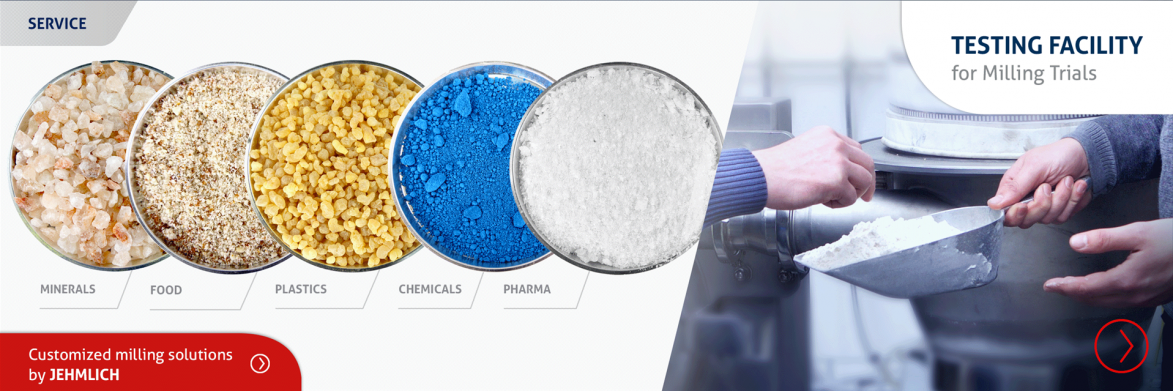

REKORD GMP-CUBE Universal Mills

Design size 224 to 630 (rotor diameter in mm)

The REKORD 224 to 630 series is a further development of the proven REKORD A to D series. For this new series, the standards of hygienic design have been implemented. This means a dead-leg-free interior design as well as a quick and easy dismantling for cleaning which is essential for pharmaceutical and food production. Depending on the design size, the mill body can be dismantled into single parts for cleaning in a validated cleaning process.

A compact and dust-proof drive case with slopes ensures a cleaning of the production area as easy as possible.

Stainless steel

Pressure shock resistant up to 10 bar in each design size

Sealing gas for bearing

With automatic lubrication system for bearing, temperature or vibration monitoring as required

FDA-compliant sealings

Internal surfaces polished Ra ≤ 0,8 µm as required

Dustproof drive case

Designed for cryogenic grinding

|

Design Size |

REKORD 224 |

REKORD 315 |

REKORD 450 |

REKORD 630 |

REKORD 630-2SSt |

|---|---|---|---|---|---|

|

Max. Drive Power [kW] |

15 |

37 |

75 |

160 |

160 |

|

Rotor Size [mm] |

224 [8.8"] |

315 [12.4"] |

450 [17.7"] |

630 [24.8"] |

630 [24.8"] |

|

Max. Circumferential Speed [m/s] |

200 |

210 |

176 |

180 |

180 |

|

Max. Capacity [kg/h]¹ |

300 |

1000 |

2500 |

5000 |

7000 |

¹ The values of maximum capacity depends on the kind of grinding stock and should provide a rough orientation. A specific dimensioning will be done in our testing facility in either case.

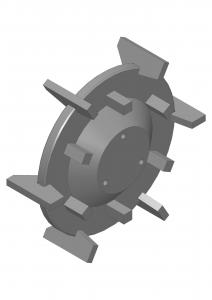

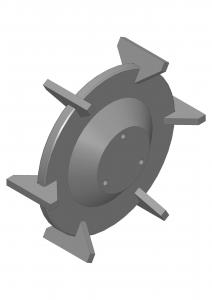

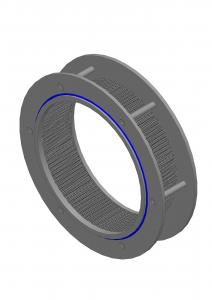

Grinding Elements for use in our Impact Mills

The specific product characteristics determine the required grinding elements. Our REKORD mills allow flexible changes of the grinding element to meet the requirements of each milling task. The grinding elements beater-disk rotor and turborotor come along with a screen plate that affects the final grain size.

Depending on the requirements, our REKORD Mills are equipped with the following grinding elements.