Grinding Plants Made of Stainless Steel - Sample Installations

Grinding Plant for Press Cake

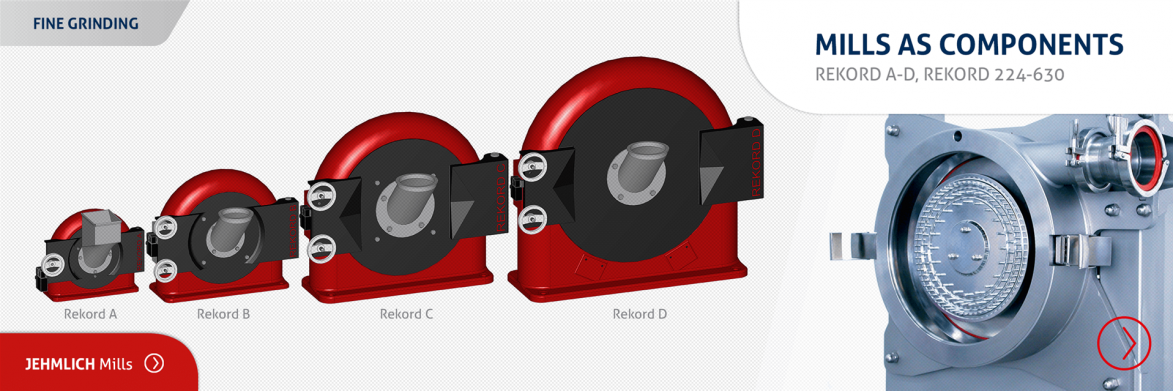

The key element of this grinding plant is the pin disk mill REKORD C-SSt. This well proven impact mill for grinding of press cakes is optimized for hygienic standards in food processing.

An efficient filter separator is used in the pneumatic conveying system.

Technical Data

Input material: press cake (hemp and mustard seeds)

Capacity: up to 450 kg/h (1000 lb/h)

Final grain size: 56% < 250 µm

Efficient filter separator

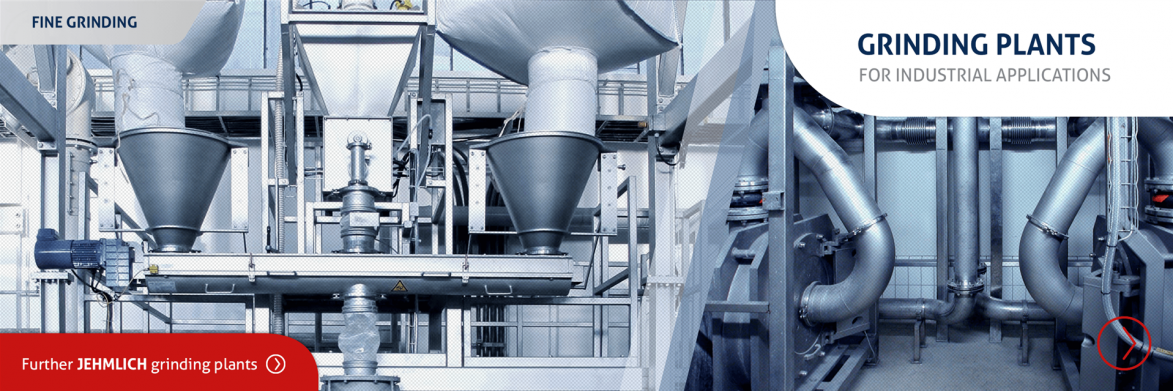

Multi-Purpose Grinding Plant for Phosphate

This multi-purpose grinding plant is separated into two sections with two walkable platforms.

In the first section the product feeding and homogenization as well as the dosing into the pneumatic conveying system is done.

For the product feeding with BIG-BAGs (each 1500 kg/3300 lb) there are two separate feeding points with lifting device. The dosage of the downstream screw conveyor is adjustable from 400 to 1000 kg/h (880 to 2200 lb/h). It is possible to add a anti-caking agent by a separate auger filler if needed. The grinding stock is homogenized to a well conveyable grain size with a Lump Breaker afterwards. The Rotary Valve WD 250 is feeding the product into the closed grinding system.

In the second section a first classification of the input material is done with a screening machine, which comes with three single screen decks.

The impact mill REKORD C-2SSt with a variable-speed drive grinds the oversized materials. A pin-disk-rotor and stator is used as grinding element and a metal separator protects them from foreign material. With a integrated conveying air conditioning it is possible to use a reduced milling air depending on the product requirements.

After refeeding of the material to the screening machine for classification the end-product is collected in BIG-BAGs on a weighing system. For a narrowly defined grain size with a constant product quality the oversized material is re-feeded to the grinding system.

Technical Data

Input material: different sodium phosphates; sodium aluminium phosphate

Capacity: up to 1000 kg/h (2200 lb/h)

Final grain size: 99 % < 200 µm (70 Mesh)

Complete design in stainless steel

Material input by two BIG-BAG discharge systems

Crane for BIG-BAG transport

Feeding of input material by Jehmlich-Screw-Conveyor

Lump breaker with extraction device after BIG-BAG discharging

Screening maschine for determination of the final grain size - 500, 200 or 150 µm (30, 70 or 100 Mesh)

Refeeding of coarse material to mill

Pin mill REKORD C-2SSt

Conveying air filter in segmental construction for quickly cleaning

Cooling system for pneumatic conveying air - to reduce the grinding temperature

Product discharge into two BIG-BAG filling stations with weighing system

Optional feeding of anti-caking agent for specific products

Operation by 19"-touchpanel

Process value archiving

Recipe management

Remote maintenance

Metal separator for mill protection and quality assurance

Pneumatic conveying as circulation system

Grinding Plant for Rose Hips

Grinding plant with beater mill REKORD B-SN for milling of dried rose hips. The plant is designed as circulation system with refeeding of coarse material.

Technical Data

Input material: rose hips, dried

Capacity: up to 200 kg/h (440 lb/h)

Final grain size: > 200 µm, < 1500 µm (> 70 Mesh, < 0.06")

Screening machine for determination of grain size

Refeeding of coarse material to mill

Separation of undersized material < 200 µm