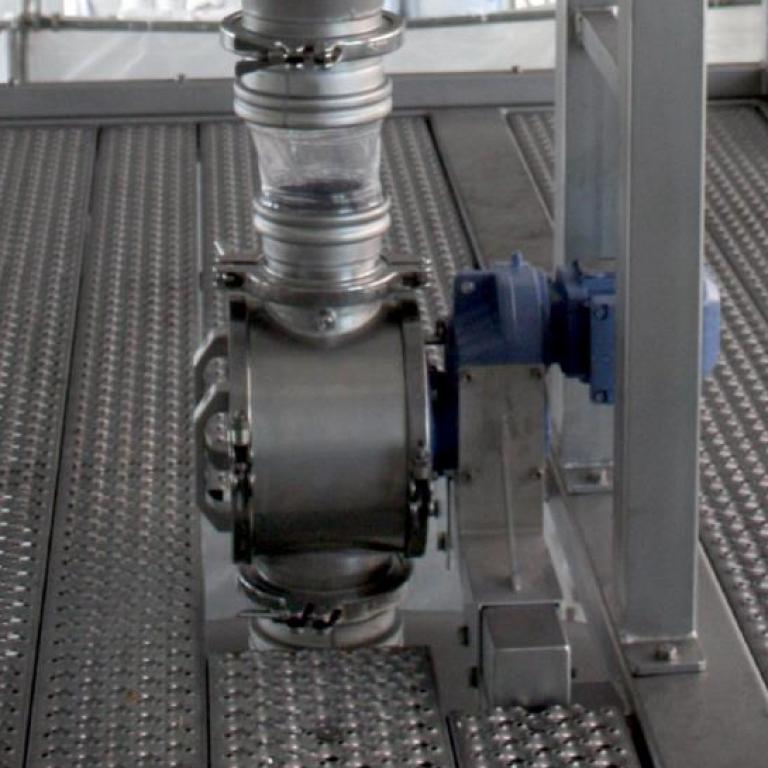

Rotary Valves in Hygienic Design

These hygienic design rotary valves are used as dosing or discharge equipment for free-flowing bulk solids. Their main field of application is the pharmaceutical and food industry. Depending on the task the rotary feeder will be equipped with different drive power and speed.

The construction consists of stainless steel 1.4404 with FDA-compliant sealings, a new developed shaft sealing with sealing gas and a GMP-compliant design with polished surfaces Ra ≤ 0,8 µm. The dismantling of the rotary valve is done by loosen of two clamp rings - for a quick and easy cleaning.

|

Design Size |

WD 150 |

WD 180 |

WD 250 |

|---|---|---|---|

|

Geared Motor |

0,25 kW |

0,25 kW |

0,37 kW |

|

Capacity |

0,53 l/revolution |

1,48 l/revolution |

5,11 l/revolution |

|

Weight |

ca. 52 kg |

ca. 64 kg |

ca. 75 kg |

|

Input/Output (DIN 32676) |

Clamp DN 80 / DN 100 |

Clamp DN 100 / DN 125 |

Clamp DN 125 / DN 150 |