Screw Feeder in GMP and Industrial Design

|

Type |

SD 63-GMP |

SD 125-GMP |

SD 160 |

|---|---|---|---|

|

Screw Diameter |

63 mm |

125 mm |

160 mm |

|

Intermediate Storage Volume |

70-100 liter |

350-500 liter |

1300 liter |

|

Application |

fine dosing of granules and bulk solids |

fine dosing of granules and bulk solids |

fine dosing and intermediate storage of granules and bulk solids; |

|

Screw Conveyor Drive |

1.1 kW |

1.5 kW |

3.0 kW |

|

Agitator Drive |

via screw conveyor drive / |

0.55 kW |

0.75 kW |

|

Capacity |

max. 0.63 m³/h |

max. 8.5 m³/h |

max. 16.5 m³/h |

|

Weight |

approx. 100 kg |

approx. 250 kg |

approx. 950 kg |

|

Discharge Diameter |

DN 63 |

DN 125 |

DN 150 |

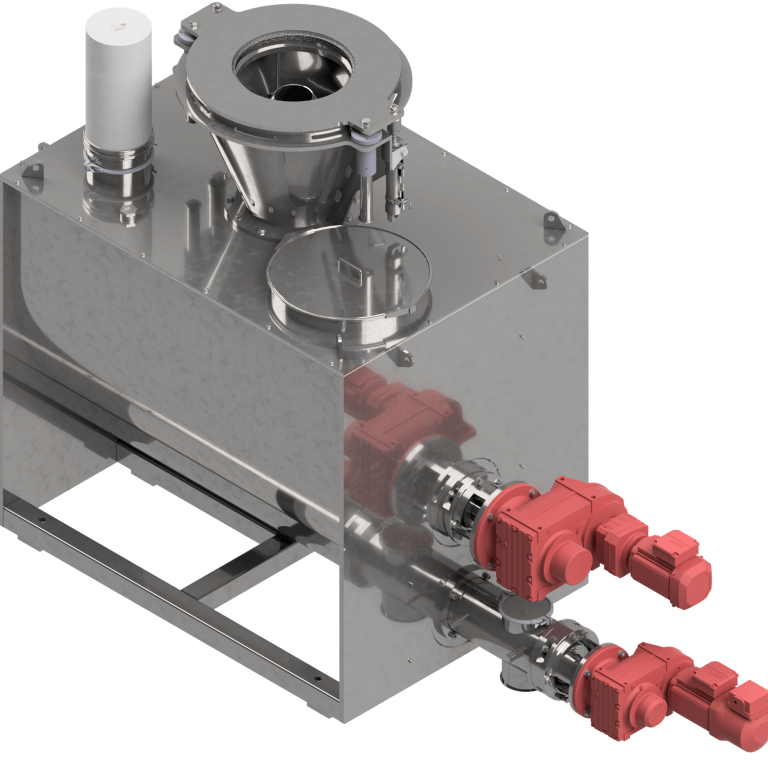

Screw Feeder SD 63 GMP

The Screw Feeder SD 63 is made from stainless steel AISI 316 with FDA-compliant seals. With its GMP design and polished surfaces it is used for applications in pharmaceutical and food industry.

The conveying screw and the agitator tool can be disassembled for quick cleaning by loosen a clamping ring.

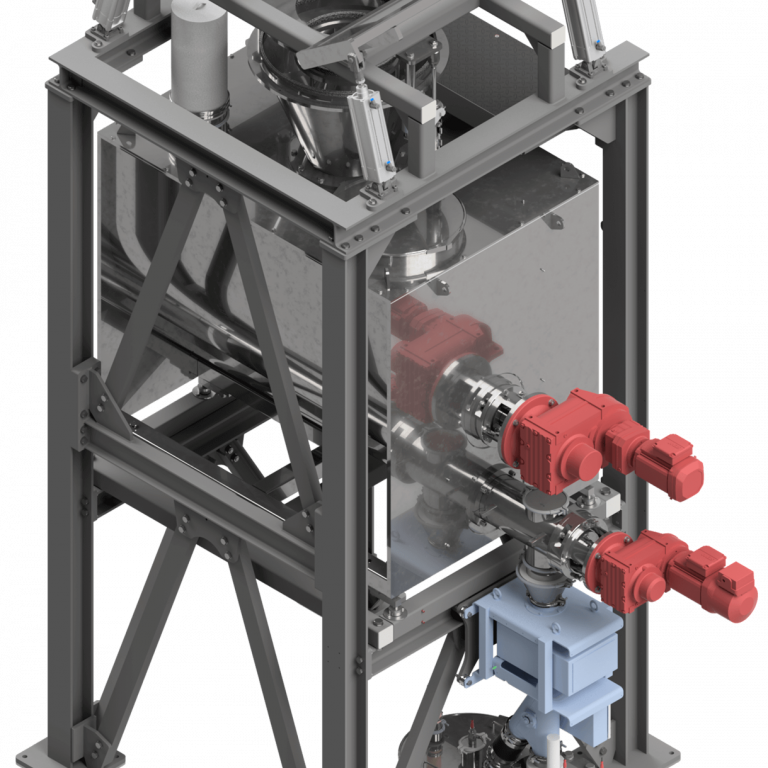

Screw Feeder SD 160 Industrial

The Screw Feeder SD 160 with its large buffer volume is optimized for usage as receiver tank or intermediate storage in bulk solids processing. With modular attachments the feeding of the screw feeder can be done from big bags, pneumatic conveying systems or on-site conveying units.

The dosing into the following process can be done either volumetric or gravimetric. With decoupling, e.g. rotary valve, the screw feeder can discharge into a pneumatic conveying system. An optional twin screw type is used in case of two separate discharge points.

Shaft sealing with packing glands secure a reliable operation while conveying abrasive materials.

For volumetric and gravimetric dosing

Material in contact with product: mild steel or stainless steel

Shaft sealings with packing glands

Level monitoring via switch or weighing system

Motion sensor for screw conveyor and agitator

Geared motors for the required ATEX zone

Optional: twin screw type for two separate discharges