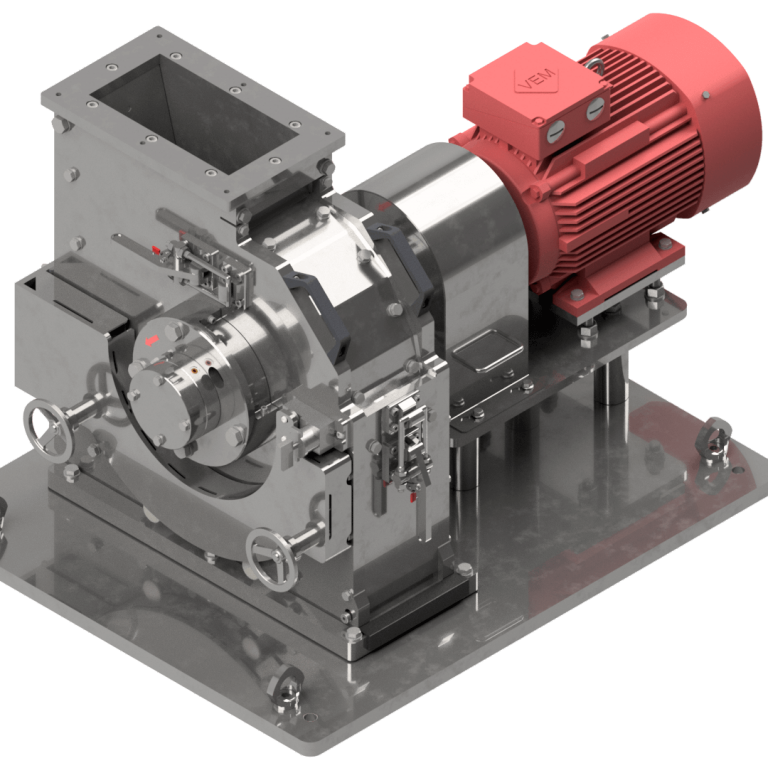

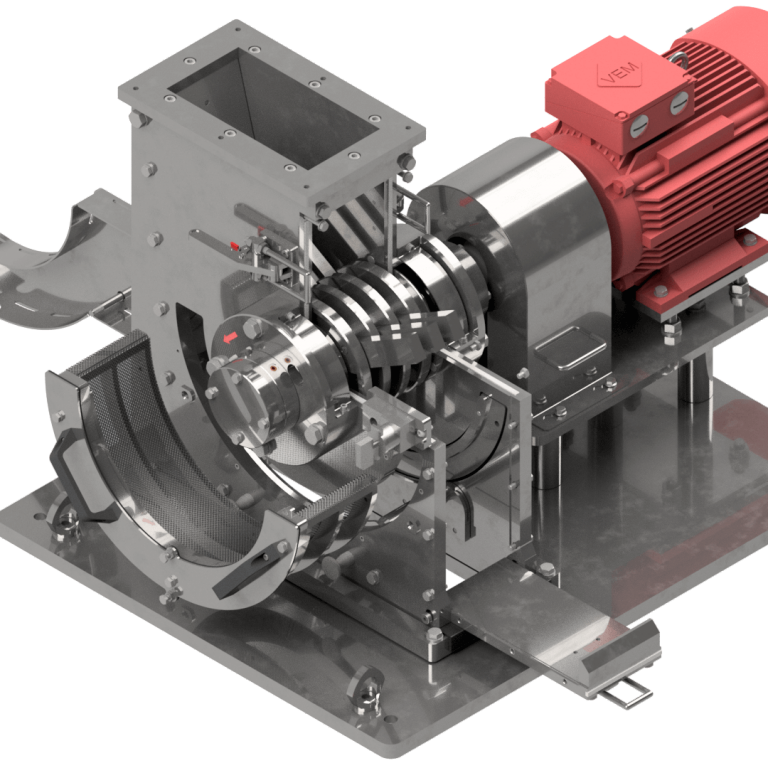

Hammer Mills

The robust, industrial hammer mills type HM 142, HM 342 and HM 672 are used for crushing materials ranging from dry to damp, soft to tough, chewy to brittle. Depending on product characteristics and the desired milling result, both types may be equipped with a variety of sieve and bar grate screen inserts. Comfortable acces to hammers, shaft and sieve insert for revision and maintenance is provided by the foldaway fronthousing. The sieve insert in easily changed from the side. The JEHMLICH hammer mills are designed for both standalone operation (batch) and direct integration into a production line.

Both types are available in mild and stainless steel.

Design Sizes of the Hammer Mills

|

Design size |

HM 142 |

HM 342 |

HM 672 |

|---|---|---|---|

|

Motor |

max. 7,5 kW (10 PS) |

max. 18,5 kW (24 PS) |

max. 45 kW (60 PS) |

|

Inlet width |

140 mm (5,5") |

340 mm (13") |

670 mm (26") |

|

Weight |

approx. 300 kg |

approx. 460 kg |

approx. 650 kg |

|

Capacity |

up to 10 t/h |

up to 20 t/h |

up to 40 t/h |

Options for stand-alone grinding stations or for product feeding/discharge as integrated systems

-

Product feeding via screw conveyor with hopper

Product feeding via screw conveyor with hopper -

Product feeding via conveyor belt with hopper

Product feeding via conveyor belt with hopper -

Integration into pneumatic conveying

Integration into pneumatic conveying -

Product feeding and discharge via rotary valves - ATEX-compliant

Product feeding and discharge via rotary valves - ATEX-compliant -

Product discharge into bags

Product discharge into bags -

Product discharge into drums

Product discharge into drums -

Manual product feeding - Product discharge into containers

Manual product feeding - Product discharge into containers -

Product discharge into screw conveyor or conveyor belt

Product discharge into screw conveyor or conveyor belt