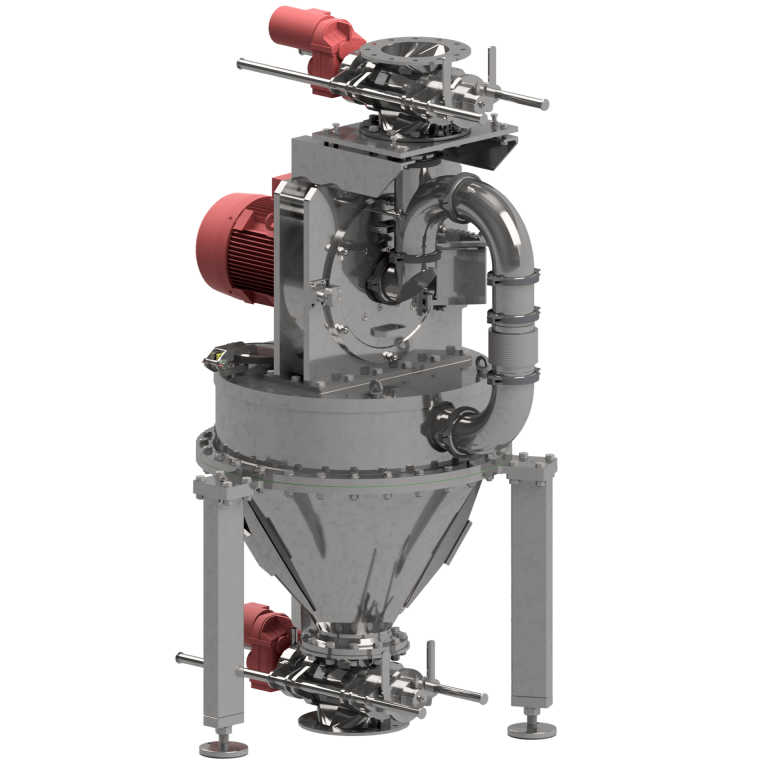

REKORD 212-630 Universal Mills

The impact mills series REKORD 212-630 are robust universal mills for a wide range of industrial grinding applications. The grinding chambers and moving parts of this mills series are by design easily accessible for revision and cleaning. The 10 bar pressure-shock resistant, welded mill housings allow processing of explosive materials (ATEX ex-zone 20 inside). High surface qualities of all parts in contact with product support a stable milling and discharge process and allow efficient cleaning of the machine. Standard mill configurations are pin rotor/stator, turbo and beater rotor with a range of sieve inserts and passive grinding elements, and rippled disc rotor/stator with a freely adjustable gap. This mills series has been designed also for cryogenic grinding processes.

|

Design Size |

REKORD 212 |

REKORD 315 |

REKORD 450 |

REKORD 630 |

REKORD 630-2SSt |

|---|---|---|---|---|---|

|

Max. Drive Power [kW] |

7,5 |

37 |

90 |

110 |

110 |

|

Rotor Size [mm] |

212 [8.3"] |

315 [12.4"] |

450 [17.7"] |

630 [24.8"] |

2x630 [24.8"] |

|

Max. Circumferential Speed [m/s] |

135 |

200 |

200 |

200 |

150 |

|

Max. Capacity [kg/h] |

300 |

1000 |

2500 |

5000 |

7000 |

Grinding Elements for use in our Impact Mills

The specific product characteristics determine the required grinding elements. Our REKORD mills allow flexible changes of the grinding element to meet the requirements of each milling task. The grinding elements beater-disk rotor and turborotor come along with a screen plate that affects the final grain size.

Depending on the requirements, our REKORD Mills are equipped with the following grinding elements.