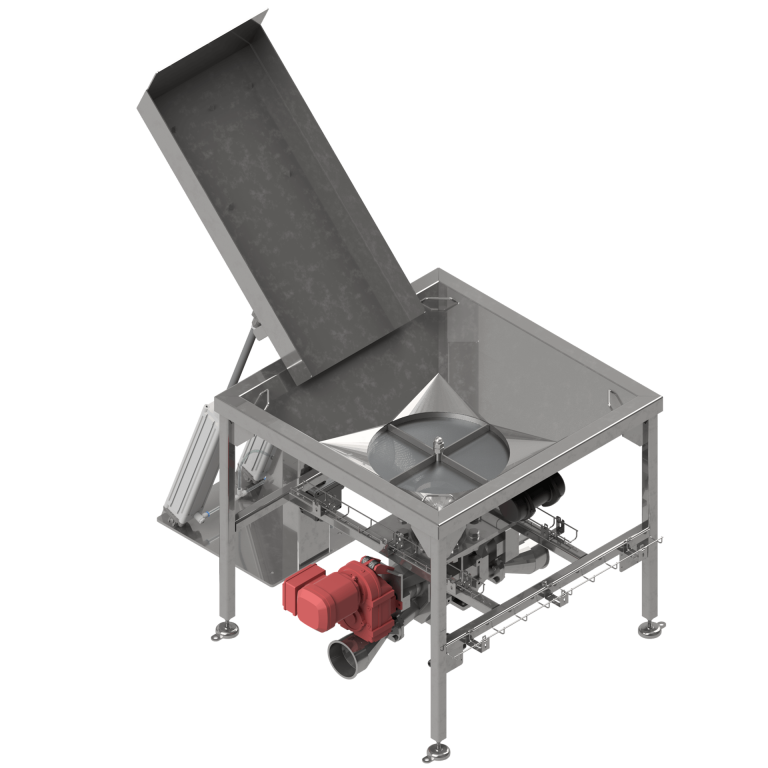

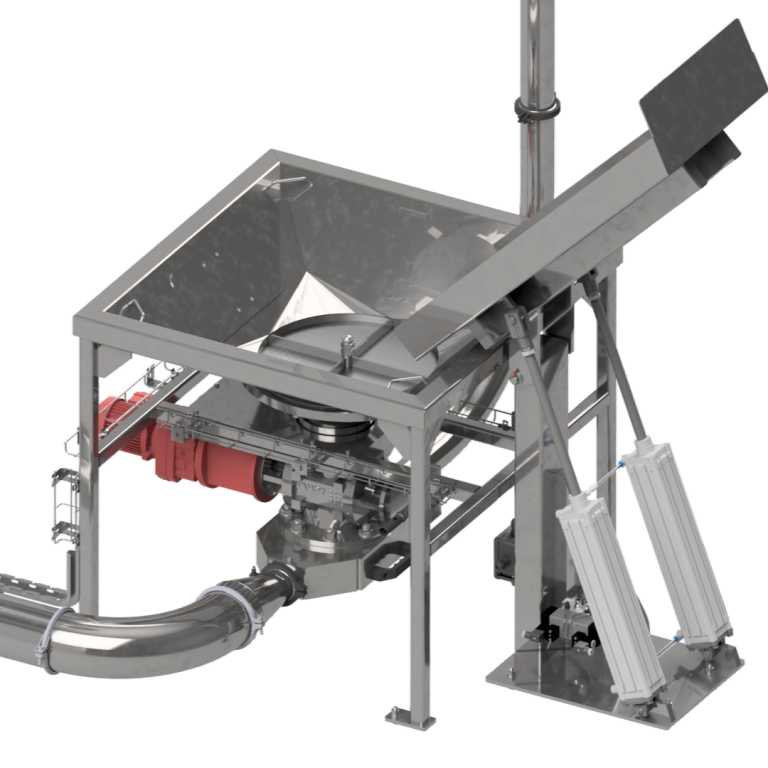

Loading Hopper with Bag Emptying Unit

The loading hopper enables filling from bags or big bags and continuously doses the ground material via a rotary valve into a pneumatic conveyor for subsequent grinding.

In addition to a magnetic separator, an integrated protective screen ensures the reliable removal of lumps, packing threads and other impurities. The hopper is equipped with a vibration motor to prevent bridging.

The feed rate of the ground material can be individually adjusted via the rotary valve.

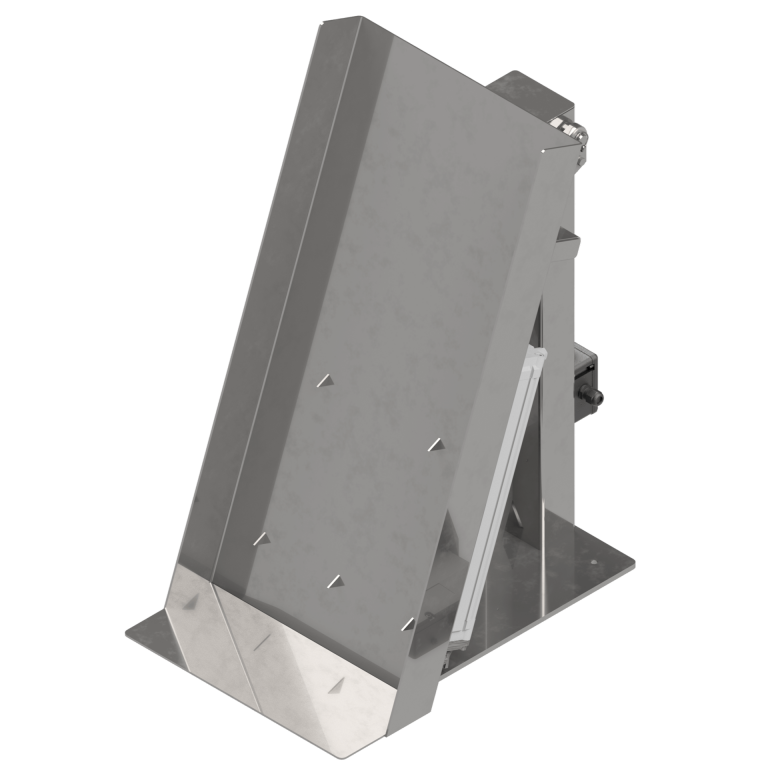

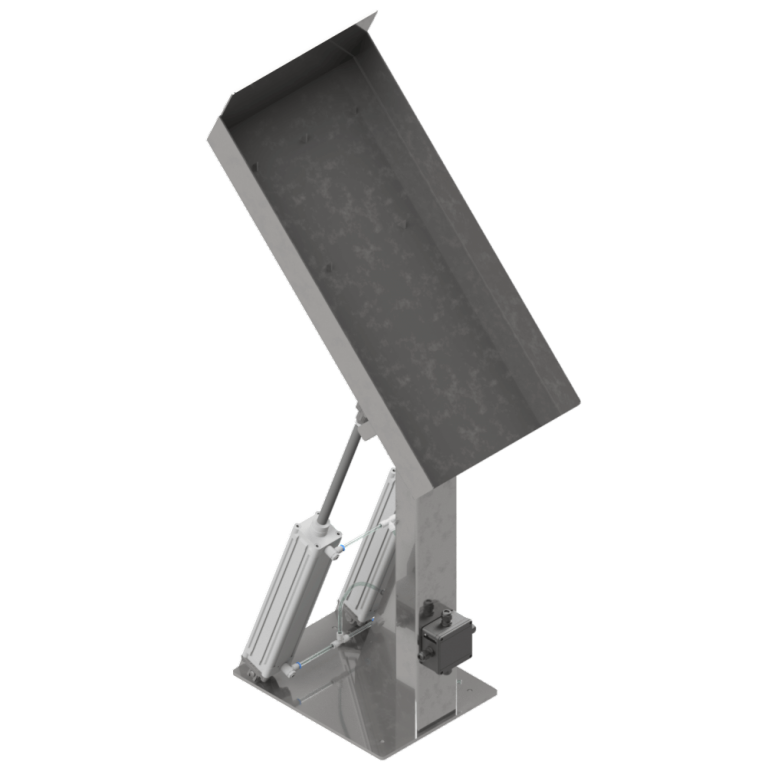

For the ergonomic emptying of bags, the dosing sieve can be equipped with the pneumatically operated bag emptying device.

Key Features

Capacity for bag filling: approx. 110 liters

Capacity for big bag filling: approx. 200 liters

Vibration motor included

Integrated protective sieve and magnetic separator

Drives for the required ATEX zone

Material in contact with product: AISI 304 or AISI 316 on request

Optional Bag Emptying Device for max. 50 kg bags