Optimization of the Design of Impact Mills for Fine Grinding of Sugar

Presentation at FIA Conference for processing and recycling in Freiberg, 9-10 November 2016

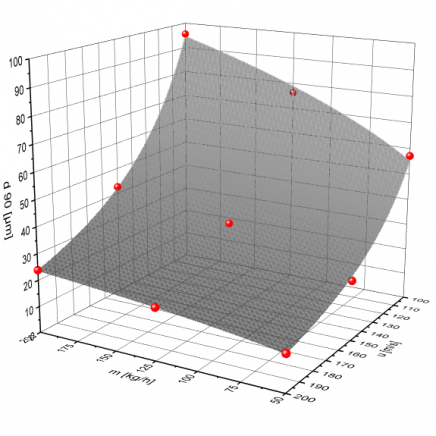

As a specialist in industrial milling technology, Gebrüder Jehmlich GmbH since its foundation in 1919 offers solutions for a wide range of milling tasks in the food & ingredients, pharmaceutical and commodities industries. A strong field of application for the JEHMLICH REKORD universal mills is the production of fine powdered sugar with a fineness of up to D90 ≤ 15 µm at a minimized temperature intake into the product. For current product specifications from the confectionery and sugar industries, the influences of grinding elements, product throughput and stressing velocity on the particle size and specific grinding energy have been investigated in cooperation with the Anhalt University of Applied Sciences.

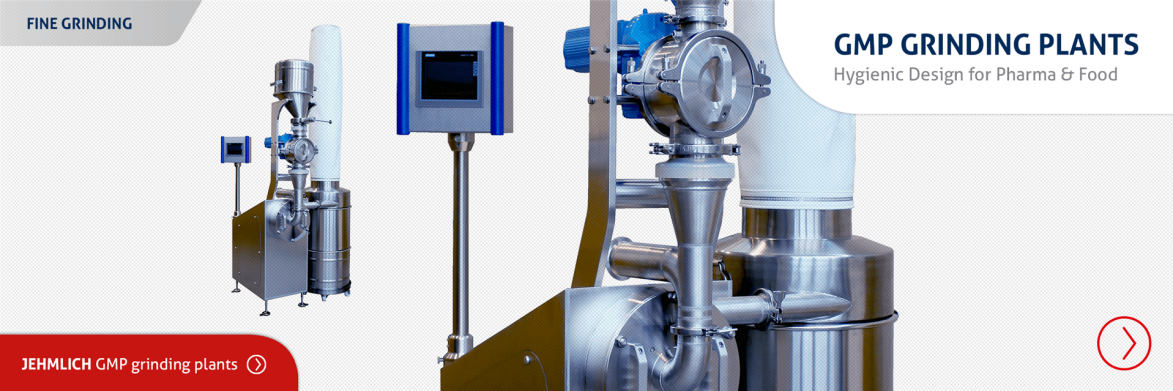

The test series has been carried out on a high-performance mill type REKORD 224-GMP in the JEHMLICH testing center. This mill has interchangeable grinding elements, such as pin discs or turbo rotors with sieve inserts. By frequency converter, the product stressing velocity can be varied up to 200 m/s. The resulting product fineness is up to d90 ≤ 15 microns at a high energy-efficiency and without any classifying.

With a newly developed tool, customers have now the opportunity to set individual and optimized operating parameters for their requirements on JEHMLICH sugar grinding systems. Based on the test results, the grinding tools can be evaluated with regard to the grinding efficiency, and relevant input variables for the upscale have been determined. JEHMLICH sugar grinding systems can be designed individually up to a capacity of 6t/h. Derived from the testing data, empirical functions can be mathematically approximated. Findings from internal research projects at JEHMLICH are regularly presented at scientific conferences to an interested audience from the food and processing industries.